Specifications

TP02

| Test method | ASTM D5334-14 and D5930-97 IEEE Std 442-1981 |

| Needle length | 150 mm |

| Traceability | NPL |

| Range (λ) | 0.1 to 6 W/m.K |

| Sensitivity (ΔT) | Thermocouple K, ANSI MC96.1-1982 |

| Temperature range (total sensor including cable) | -55 to +180 °C |

| Accuracy (@ 20 °C) | ± (3% + 0.02) W/mK |

| Temperature dependence of the accuracy | ± 0.02 %/K (additional) |

| Heating cycle duration | 100 s (typical) |

| Power requirements (switched) | 3V, 1 Watt (max) |

| Medium / sample requirements | granular materials, powders, slurries, gels, pastes. Some samples require predrilling. Sample size: Min 20 mm radius. Smaller samples: consult Hukseflux. Caution: please consult the product manual for more details. |

| Protection needle and base | IP68 |

| Protection total sensor | IP67 |

Options

- Alternative designs: Hukseflux is specialised in NSSP design. Alternative models, for instance smaller (see model TP08), more robust or temperature resistant have been manufactured on request.

- Permanent installation in soils: The dedicated model TP01 is specifically designed for long term monitoring. A separate brochure is available.

- Solutions for measurement and control: See the TP02 manual or inquire at Hukseflux. A program for Campbell Scientific CR10X is available. Turn key systems are offered for sale: see TPSYS.

Downloads

(PDF, 255.21 KB)

(PDF, 690.74 KB)

Optimal Accuracy: TP02 incorporates 2 thermocouple junctions in the needle producing a voltage output, U, that is proportional to ΔT. The one in the tip is not heated. The main signal is the differential signal between this hot joint at 1/3 of the length and the cold joint at the tip. In this configuration the voltage before starting the measurement is always small, independent of the medium temperature. In designs with only one sensor in the needle, the signal U will appear on top off a larger signal. The two junction design has a superior accuracy when measuring at high and low temperatures. In addition, by having both the cold- and the hot junction in the needle, the sensitivity to temperature changes of the medium is minimised.

Temperature sensor in the base: The reference temperature sensor in the base (Pt1000) serves as a “cold junction” measurement for establishing the absolute medium temperature T. This is required by ASTM.

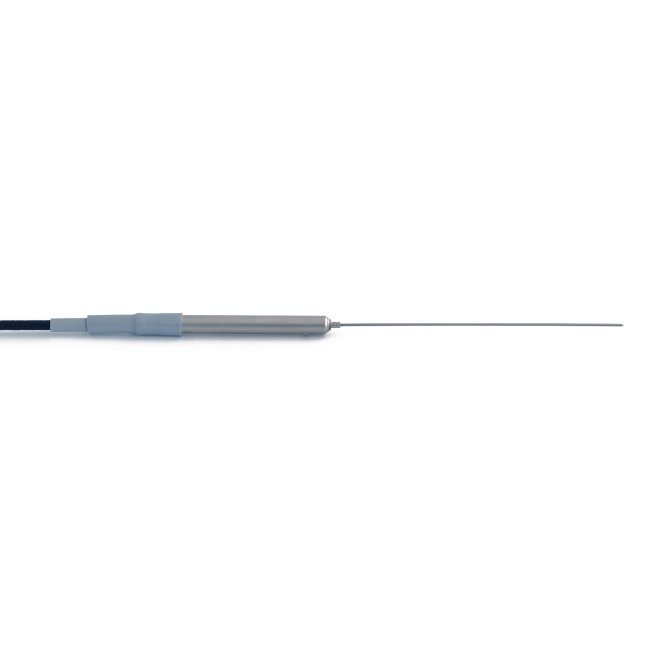

Temperature and moisture resistance: All the materials in TP02 are highly temperature resistant. It has a full stainless steel needle and base. TP02 is completely sealed. It has a welded tip. This no-compromise sealing guarantees the long term stability of the sensor. Designs with glued sealing or epoxy housings are less reliable in this respect, particularly when working in moist environments.

Standard cables and connectors: Putting the Pt1000 temperature sensor in the base allows the use of normal copper core cables and connectors for cable extension of TP02.

Data processing: The data obtained with TP02 can be processed in any normal spreadsheet program.

Suggested use

- studies of soils and soft rock

- studies of foodstuff, plastics and powders

Areas of Application

CRC series

TP02 thermal properties sensor

- optimal accuracy

- temperature sensor in the base

- high temperature and moisture resistance