Specifications

IHF02

| Measurand | heat flux, temperature |

| Measurement range | (-100 to 100) x 10³ W/m² |

| Sensitivity (nominal) | 250 x 10⁻⁹ V/(W/m²) |

| Heat flux sensor | thermopile |

| Temperature sensor | thermocouple type K |

| Calibration traceability | to SI units |

| Recommended number of sensors | 2 per measurement location |

| Rated operating temperature ranges | |

| sensor and high-temperature cable | -30 to +900 °C |

| optional black coating | -30 to +650 °C |

| optional magnet frame | -30 to +500 °C |

| low-temperature extension cable | -30 to +240 °C |

| IP protection class | IP67 |

| Standard cable lengths | |

| high-temperature cable | 1 m (see options) |

| low-temperature extension cable | 3 m (see options) |

| Order code | IHF02 - high temperature cable length in m - low temperature extension cable length in m |

Options

- magnet frame

- black coating

- longer cable

- EC type examination certificate (ATEX) II 2G Ex db IIC T6

- connector at IHF02 cable end

- low-temperature extension cable with 2 connectors, matching cable connector and chassis connector

- chassis connector with internal wiring (colour code of wiring identical to cable colour code)

Downloads

(PDF, 2.13 MB)

(PDF, 3.83 MB)

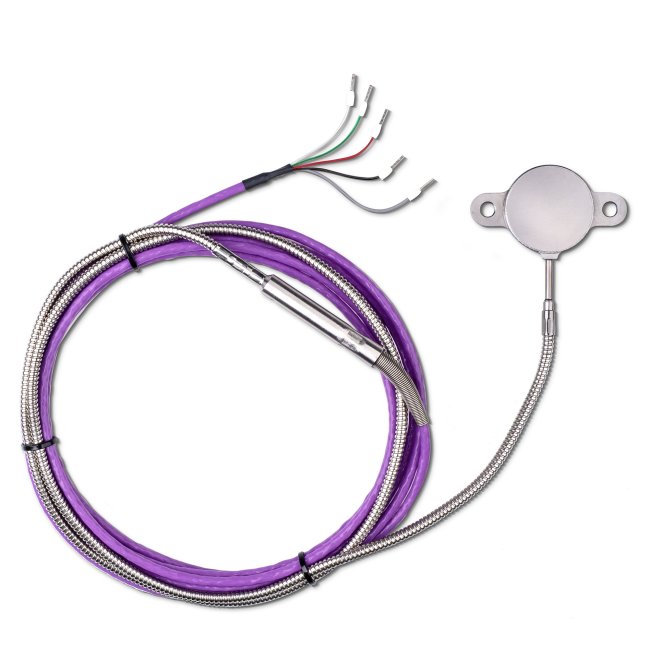

IHF02 measures heat flux and surface temperature of industrial equipment like furnaces, boilers, fluidised beds, distillation columns and ovens. The sensors inside IHF02, a thermopile and a type K thermocouple, are protected by a fully sealed stainless steel body. It is suitable for long-term use at one location as well as surveys at multiple locations. IHF02 measures heat flux through the object on which it is mounted, in W/m², as well as the temperature in °C. An optional magnet frame is offered for easy mounting on magnetic surfaces.

IHF02 is 25 times more sensitive than model IHF01, so that, with the same measurement accuracy of its output voltage, it can be used to measure much lower heat flux levels. When equipped with the optional magnet frame and optional black coating, IHF02 replaces model HF01 high temperature heat flux sensor. The part of the cabling closest to the sensor is a special high-temperature metal sheathed cable with an interlocked spiral stainless steel armour. The sensor as well as the high-temperature cable and armour withstand temperatures up to 900 °C. The temperature range is reduced to 650 °C in case the optional black coating is used. The magnet frame can be used up to 500 °C. The low-temperature extension cable has a jacket of PTFE type plastic.

Using IHF02 is easy. It can be connected directly to commonly used data logging systems. The heat flux, in W/m², is calculated by dividing the IHF02 output, a small voltage, by the sensitivity. The sensitivity is provided with IHF02 on its product certificate. The temperature sensor is a conventional type K thermocouple. Equipped with heavy-duty cabling and a fully stainless steel casing, preventing moisture from penetrating the sensor, IHF02 has proven to be very reliable. It survives long-term outdoor installation.

IHF02 is most suitable for relative measurements, i.e. monitoring of trends relative to a certain reference point in time or comparing heat flux at one location to the heat flux at another location. If the user wants to perform accurate absolute measurements with IHF02, as opposed to relative measurements, the user must make his own uncertainty evaluation and correction for systematic errors.

IHF02 calibration is traceable to international standards. The factory calibration method follows the recommended practice of ASTM C1130-17. IHF02 is calibrated at room temperature, mounted on a metal heat sink.

Suggested use

trend-monitoring and comparative measurement of heat flux and surface temperature in industrial installations, such as the shell of aluminium reduction cells.

Areas of Application

IHF02 heat flux sensor

- high sensitivity

- robust

- suitable for use at high temperatures

- IP protection class: IP67

- signal wires electrically insulated from the sensor body